Amtest UK offers professional pull-out testing to assess the strength and security of bolts, screws, anchors, and fixings. This test ensures that these critical components can withstand the designed stress loads, providing confidence in their performance and safety.

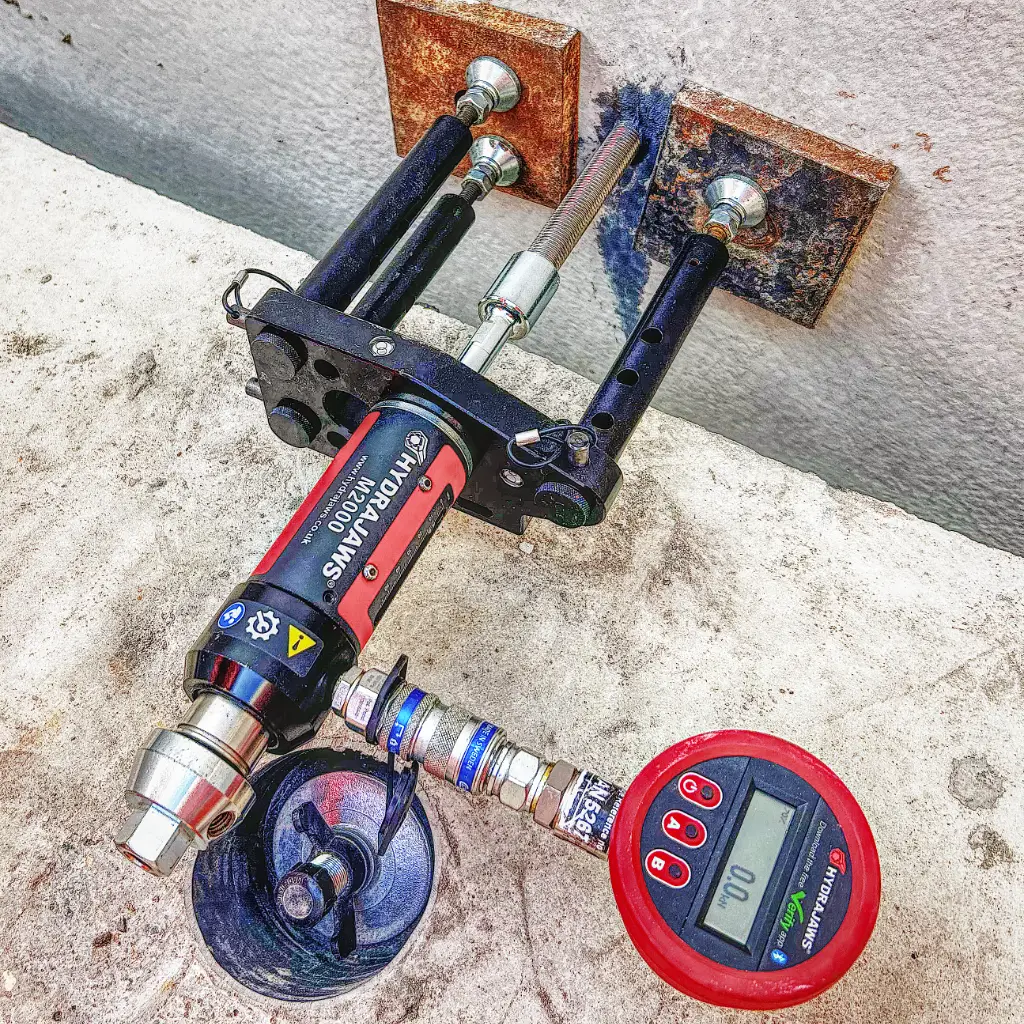

Pull-out testing involves attaching a specialised test rig to the fixing and applying tension to simulate real-world stress conditions. The test determines the maximum load the fixing can bear before failure or deformation, providing vital data for construction and engineering applications.

AMTEST UK Ltd delivers top-tier services to civil engineering and infrastructure clients across the UK, backed by expert in-house concrete consultants.

Unit A 2D/6, Project Park, North Crescent, London E16 4TQ

Amtest UK offers professional pull-out testing to assess the strength and security of bolts, screws, anchors, and fixings. This test ensures that these critical components can withstand the designed stress loads, providing confidence in their performance and safety.

Pull-out testing involves attaching a specialised test rig to the fixing and applying tension to simulate real-world stress conditions. The test determines the maximum load the fixing can bear before failure or deformation, providing vital data for construction and engineering applications.